Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. Mechanical Transmission Parts Co., Ltd. is a professional manufacturer of mechanical transmission parts, founded in 1987. Our company is committed to standard roller sprocket, single row and multi-row sprocket, non-standard sprocket, gear, rack, bevel gear, sprocket, shaft, gear shaft and other products. We have passed ISO 9001 .Xihu (West Lake) Dis. company has a number of experienced engineers, involved in plHangZhou, testing, heat treatment, inspection, the use of strict and accurate testing methods. Our sprockets are widely used in agricultural machinery, stereoscopic garage, mining equipment, woodworking machinery, petroleum machinery and other industries. Implementation standards such as ANSI.BS, DIN.KANA, etc., can also be customized according to the drawing processing

Our products have won wide praise and trust from customers for their excellent quality. HangZhou Xihu (West Lake) Dis. mechanical transmission Parts Co., Ltd. adhere to the quality of survival, innovation and development, customer first business philosophy, dedicated to domestic and foreign customers service. We warmly welcome you to negotiate business with us.

Product Description

| Standard or Nonstandard | Standard | Application | Maqchinery | |

| Hardness | Hardened Tooth Surface | Material | C45 | |

| Specification | Various Sprockets | Pitch(PCD) | 1-10M | |

| Toothed Portion Shape | Spur Gear | Teeth | 10-60Z | |

| HS Code | 84839000 | Production Capacity | 100000 Pcs/Year |

Detailed Photos

Certifications

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3d drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample free sample

|

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you retrofit an existing mechanical system with spur gears?

Retrofitting an existing mechanical system with spur gears involves modifying or replacing certain components to incorporate spur gears into the system. Here’s a detailed explanation:

1. Evaluate the Existing System:

Begin by thoroughly evaluating the existing mechanical system to determine its design, function, and limitations. Identify the specific components that need to be retrofitted with spur gears and understand how the system operates.

2. Design Considerations:

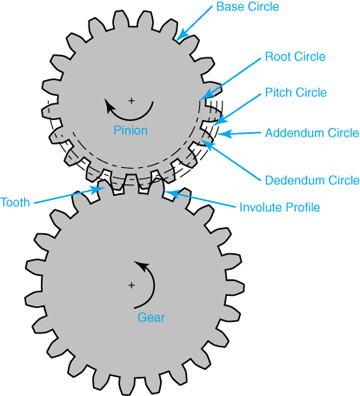

Based on the evaluation, consider the design considerations for integrating spur gears into the system. This includes factors such as gear size, tooth profile, gear material, gear ratio, and torque requirements. Determine the specific gear specifications that are compatible with the existing system.

3. Gear Selection:

Select the appropriate spur gears that meet the required specifications. Consider factors such as gear quality, load capacity, noise level, efficiency, and compatibility with the existing system components. Choose gears from reputable manufacturers or consult with a gear specialist for guidance.

4. Gear Positioning and Alignment:

Determine the optimal positioning and alignment of the spur gears within the existing system. This involves identifying the gear locations, shaft connections, and ensuring proper alignment with other components such as bearings and couplings. Accurate positioning and alignment are crucial for efficient gear operation and longevity.

5. Modification or Replacement:

Based on the design considerations and gear selection, proceed with the necessary modifications or replacements. This may involve removing existing components, such as gears with different tooth profiles, and replacing them with the selected spur gears. Ensure proper installation and secure attachment of the new gears.

6. Lubrication and Maintenance:

Implement appropriate lubrication practices for the newly retrofitted spur gears. Consult gear manufacturers’ recommendations for lubricant type, quantity, and maintenance intervals. Proper lubrication ensures smooth gear operation, reduces wear, and extends gear life.

7. Testing and Validation:

After the retrofitting process, conduct thorough testing and validation of the modified system. Verify that the spur gears are functioning as intended, ensuring proper engagement, smooth operation, and adequate load handling. Address any issues or discrepancies discovered during testing.

8. Documentation and Training:

Create documentation detailing the retrofitting process, including gear specifications, installation procedures, and maintenance requirements. This documentation serves as a reference for future maintenance and helps ensure consistent gear performance. Additionally, provide training to relevant personnel on the operation, maintenance, and troubleshooting of the retrofitted system.

Retrofitting an existing mechanical system with spur gears requires careful planning, proper gear selection, precise installation, and thorough testing. By following these steps and considering the specific requirements of the system, it is possible to successfully incorporate spur gears and enhance the performance and functionality of the mechanical system.

What is the lifespan of a typical spur gear?

The lifespan of a typical spur gear can vary significantly depending on several factors. Here’s a detailed explanation:

The lifespan of a spur gear is influenced by various factors, including:

- Operating Conditions: The conditions under which the spur gear operates greatly impact its lifespan. Factors such as the magnitude and frequency of the applied loads, operating temperature, speed, and lubrication quality play a significant role. Gears operating under heavy loads, high speeds, or harsh environments may experience higher wear and fatigue, potentially reducing their lifespan.

- Material Selection: The material used for constructing the spur gear affects its durability and lifespan. Spur gears are commonly made from materials such as steel, cast iron, bronze, or polymer composites. The specific material properties, including hardness, strength, and resistance to wear and corrosion, influence the gear’s ability to withstand the operating conditions and determine its lifespan.

- Quality of Manufacturing: The quality of manufacturing processes and techniques employed during the production of the spur gear can impact its lifespan. Gears manufactured with precision, accurate tooth profiles, and proper heat treatment are more likely to have longer lifespans compared to those with manufacturing defects or poor quality control.

- Lubrication and Maintenance: Proper lubrication is crucial for reducing friction, wear, and heat generation in spur gears. Regular maintenance practices, including lubricant replacement, gear inspections, and addressing any issues promptly, can significantly extend the lifespan of the gears. Inadequate lubrication or neglecting maintenance can lead to premature wear and failure.

- Load and Stress Distribution: The design and configuration of the gear system affect the load and stress distribution on the spur gears. Proper gear design, including tooth profile, number of teeth, and gear arrangement, helps ensure even load distribution and minimizes localized stress concentrations. Well-designed supporting components, such as bearings and shafts, also contribute to the overall lifespan of the gear system.

It is challenging to provide a specific lifespan for a typical spur gear since it depends on the aforementioned factors and the specific application. Spur gears can have lifespans ranging from several thousand to millions of operating cycles. Industrial gear systems often undergo regular inspections and maintenance, including gear replacement when necessary, to ensure safe and reliable operation.

It’s important to note that gear lifespan can be extended through proper care, maintenance, and adherence to recommended operating parameters. Regular inspections, monitoring of gear performance, and addressing any signs of wear or damage promptly can help maximize the lifespan of spur gears.

When assessing the lifespan of spur gears for a particular application, it is advisable to consult manufacturers, industry standards, and experts with expertise in gear design and maintenance for accurate estimations and recommendations.

How do spur gears contribute to power transmission?

Spur gears play a crucial role in power transmission due to their specific design and tooth engagement. Here’s a detailed explanation of how spur gears contribute to power transmission:

- Direct Tooth Engagement: Spur gears have straight teeth that mesh directly with each other. This direct tooth engagement ensures efficient transfer of power from one gear to another. As the driving gear rotates, its teeth come into contact with the teeth of the driven gear, enabling the transfer of rotational motion and torque.

- Uniform Load Distribution: The teeth of spur gears distribute the transmitted load evenly across the gear surfaces. The straight, parallel teeth provide a larger contact area compared to other gear types, resulting in improved load-carrying capacity and reduced stress concentration. This uniform load distribution helps prevent premature wear and failure of the gears, ensuring reliable power transmission.

- Efficiency: Spur gears are known for their high efficiency in power transmission. The direct tooth engagement and parallel shaft arrangement minimize energy losses during rotation. The teeth mesh smoothly, resulting in minimal friction and reduced power dissipation. This efficiency is beneficial in applications where maximizing power transfer and minimizing energy waste are crucial.

- Speed and Torque Conversion: Spur gears allow for speed and torque conversion between the driving and driven shafts. By using gears with different numbers of teeth, the rotational speed and torque can be adjusted to match the requirements of the application. For example, a small gear driving a larger gear will result in a higher torque output at a lower speed, while a larger gear driving a smaller gear will result in a higher speed output at a lower torque.

- Directional Control: The arrangement of spur gears can be used to control the rotational direction of the driven shaft relative to the driving shaft. By meshing gears with opposite orientations (e.g., one gear with clockwise teeth and another gear with counterclockwise teeth), the direction of rotation can be reversed. This directional control is essential in applications where the desired motion needs to be reversed or changed.

- Multiple Gear Configurations: Spur gears can be combined in various configurations to form gear trains, allowing for complex power transmission systems. Gear trains consist of multiple gears meshing together, with each gear contributing to the overall power transmission. Gear trains can alter speed, torque, and direction, providing flexibility in adapting power transmission to specific requirements.

- Compatibility with Other Components: Spur gears are compatible with a wide range of other mechanical components, such as shafts, bearings, and housings. This compatibility allows for easy integration into different systems and machinery. Spur gears can be mounted on shafts using keyways, set screws, or other mounting methods, ensuring secure and reliable power transmission.

Overall, spur gears are essential in power transmission systems due to their direct tooth engagement, uniform load distribution, high efficiency, speed and torque conversion capabilities, directional control, compatibility with other components, and the ability to form complex gear trains. These characteristics make spur gears a versatile and widely used choice for transmitting power in various applications across industries.

editor by CX 2023-09-18