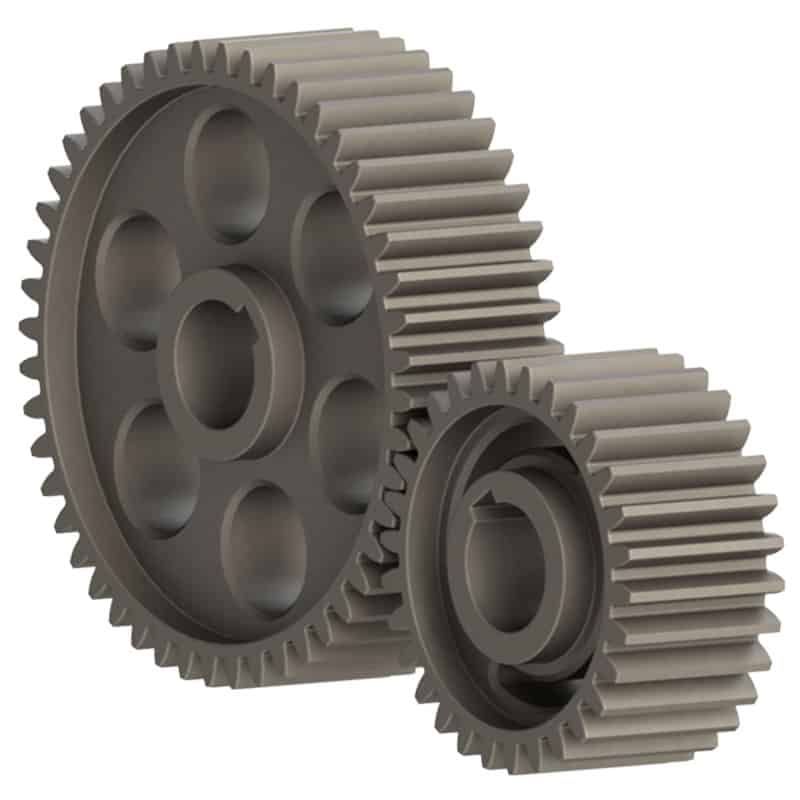

Product Description

Product introduction

| Gear model | Customized gear accoding to customers sample or drawing |

| Processing machine | CNC machine |

| Material | 20CrMnTi/ 20CrMnMo/ 42CrMo/ 45#steel/ 40Cr/ 20CrNi2MoA |

| Heat treattment | Carburizing and quenching/ Tempering/ Nitriding/ Carbonitriding/ Induction hardening |

| Hardness | 58-62HRC |

| Qaulity standerd | GB/ DIN/ JIS/ AGMA |

| Accuracy class | 5-8 class |

| Shipping | Sea shipping/ Air shipping/ Express |

Factory introduction

ZheJiang Yingxing Gear Co., LTD is set product development, production and sales of specialized enterprises, the company was founded in 2007, is located in Xihu (West Lake) Dis. Bridge River, 50 kilometers from the provincial capital HangZhou city, convenient transportation.

The company has modern professional production workshop covers an area of 30,000 square meters, 120 employees, including professional and technical staff of 30 people. We buy the advanced processing center equipment from Germany and American. We produce the gear for reducer,agricultural machinery, construction machinery, oil drilling rig,and other aspects of the production. The company has been appraised as ZheJiang quality products, corporate credit quality units. The company has offices in HangZhou.

Our products sell well in China and exported to Europe, the Americas, the Middle East, Southeast Asia and other countries. My company adhered to the “good faith, winning by quality, first-class service will be presented to our customers” for the purpose, we are willing to be honest with you, and work together for a better tomorrow.

Factory pictures and cerfitication

| Application: | Machinery, Marine, Agricultural Machinery, Drilling Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | 20crmnti |

| Customization: |

Available

| Customized Request |

|---|

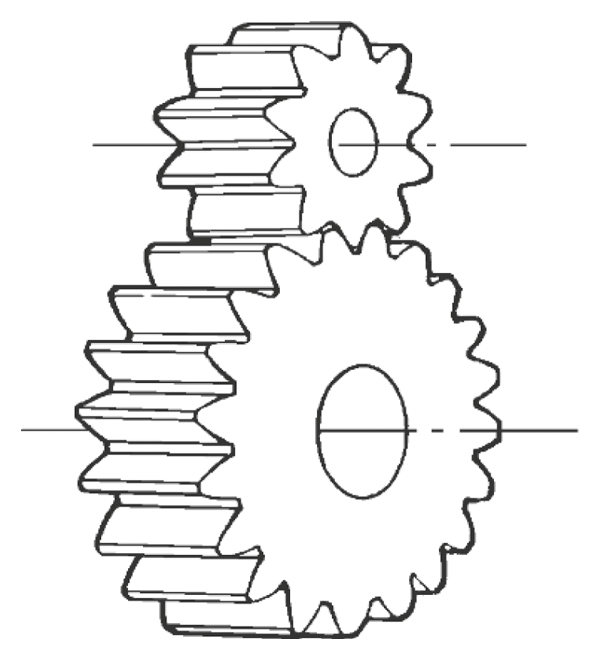

Can spur gears be used in precision manufacturing equipment?

Yes, spur gears can be used in precision manufacturing equipment. Here’s a detailed explanation:

Precision manufacturing equipment requires high accuracy, repeatability, and reliability to produce intricate and precise components. While other gear types like helical gears or bevel gears are commonly used in precision applications, spur gears can also be suitable in certain scenarios.

1. Low-Speed Applications:

Spur gears are well-suited for low-speed applications where high precision is required. In precision manufacturing equipment, such as milling machines, lathes, or grinding machines, where controlled and precise rotational motion is essential, spur gears can provide the necessary power transmission with accuracy.

2. Linear Actuators and Positioning Systems:

Spur gears can be used in linear actuators and positioning systems within precision manufacturing equipment. These systems require precise movement control, and spur gears can convert rotary motion into linear motion accurately. By incorporating precision-ground spur gears with proper backlash control, highly accurate positioning can be achieved.

3. Tooling Systems:

Spur gears are employed in tooling systems used in precision manufacturing equipment, such as indexing heads and rotary tables. These systems enable precise and repeatable positioning of workpieces or cutting tools. Spur gears with high precision tooth profiles and low backlash are utilized to ensure accurate tool positioning and consistent machining results.

4. Measuring and Inspection Equipment:

In precision manufacturing, gear systems are also utilized in measuring and inspection equipment. Spur gears can be incorporated into gear trains within instruments like coordinate measuring machines (CMMs) or optical comparators to translate linear or rotary motion into precise measurement data. The gear systems in these instruments require minimal backlash and high accuracy to ensure accurate measurements.

5. Customized Gear Systems:

In some cases, precision manufacturing equipment may require custom-designed gear systems to meet specific application requirements. Spur gears can be tailored and optimized for these custom gear systems, taking into account factors like gear tooth profile, material selection, and gear geometry. This allows for the creation of highly precise and specialized gear systems.

While spur gears have advantages in precision manufacturing equipment, it’s important to consider their limitations. Due to their design, spur gears may produce more noise and vibration compared to other gear types. Additionally, they are generally not suitable for high-speed or high-torque applications that demand continuous and smooth power transmission.

Overall, spur gears can be successfully used in precision manufacturing equipment for specific applications that require low-speed, precise motion control, accurate positioning, and measurement capabilities. Proper gear selection, high-quality manufacturing, and careful system integration are key to achieving the desired precision and performance in these gear applications.

Can you provide examples of machinery that use spur gears?

Spur gears are widely used in various machinery and mechanical systems due to their simplicity, efficiency, and versatility. Here are some examples of machinery and equipment that commonly utilize spur gears:

- Automotive Industry: Spur gears are found in various automotive applications, including manual transmissions, differential gears, and starter motors. They are used to transmit power and torque efficiently in these systems.

- Mechanical Clocks and Watches: Traditional mechanical clocks and watches often utilize spur gears to transfer rotational motion from the mainspring to the hour, minute, and second hands. These gears play a crucial role in accurate timekeeping.

- Printing Presses: Spur gears are employed in printing presses to synchronize the movement of different components, such as rollers and paper feed mechanisms. They ensure precise and coordinated operation during the printing process.

- Industrial Machinery: Many types of industrial machinery rely on spur gears, including conveyors, packaging equipment, textile machinery, and machine tools. Spur gears help transmit power and control the movement of various components in these machines.

- Power Plants: Spur gears can be found in power generation facilities, such as steam turbines and gas turbines. They help transfer rotational motion from the turbine shaft to the generator shaft, enabling the production of electrical power.

- Agricultural Equipment: Agricultural machinery, such as tractors, combines, and harvesters, often utilize spur gears in their drive systems. These gears help transmit power from the engine to the wheels or other operational components.

- Robotics and Automation Systems: Spur gears are commonly used in robotics and automation systems to transmit power and control the movement of robotic arms, conveyor systems, and other mechanical components.

- Power Tools: Many power tools, including drills, saws, and grinders, incorporate spur gears in their gearboxes. These gears help increase torque and provide the necessary speed reduction for efficient tool operation.

These examples represent just a few of the many applications where spur gears are utilized. Spur gears’ simplicity, cost-effectiveness, and ability to handle high load capacities make them suitable for a wide range of machinery and mechanical systems in various industries.

It’s important to note that different gear types, such as helical gears, bevel gears, or planetary gears, may also be used in conjunction with spur gears or in different applications depending on specific requirements and design considerations.

Are there different sizes and configurations of spur gears available?

Yes, there are various sizes and configurations of spur gears available to suit different applications and requirements. Here’s a detailed explanation of the different options when it comes to sizes and configurations of spur gears:

Sizes: Spur gears come in a wide range of sizes to accommodate different torque and speed requirements. The size of a spur gear is typically specified by its pitch diameter, which is the diameter of the pitch circle. The pitch diameter determines the gear’s overall size and the spacing between the teeth. Spur gears can range from small gears used in precision instruments to large gears used in heavy machinery and industrial equipment.

Module: Module is a parameter used to specify the size and spacing of the teeth on a spur gear. It represents the ratio of the pitch diameter to the number of teeth. Different module sizes are available to accommodate various gear sizes and applications. Smaller module sizes are used for finer tooth profiles and higher precision, while larger module sizes are used for heavier loads and higher torque applications.

Number of Teeth: The number of teeth on a spur gear can vary depending on the specific application. Gears with a higher number of teeth provide smoother operation and distribute the load more evenly, whereas gears with fewer teeth are typically used for higher speeds and compact designs.

Pressure Angle: The pressure angle is an important parameter that determines the shape and engagement of the teeth. Common pressure angles for spur gears are 20 degrees and 14.5 degrees. The selection of the pressure angle depends on factors such as load capacity, efficiency, and specific design requirements.

Profile Shift: Profile shift is a design feature that allows modification of the tooth profile to optimize the gear’s performance. It involves shifting the tooth profile along the gear’s axis, which can affect factors such as backlash, contact ratio, and load distribution. Profile shift can be positive (when the tooth profile is shifted towards the center of the gear) or negative (when the tooth profile is shifted away from the center).

Hub Configuration: The hub refers to the central part of the gear where it is mounted onto a shaft. Spur gears can have different hub configurations depending on the specific application. Some gears have a simple cylindrical hub, while others may have keyways, set screws, or other features to ensure secure and precise mounting.

Material and Coatings: Spur gears are available in various materials to suit different operating conditions and requirements. Common materials include steel, cast iron, brass, and plastic. Additionally, gears can be coated or treated with surface treatments such as heat treatment or coatings to enhance their wear resistance, durability, and performance.

Mounting Orientation: Spur gears can be mounted in different orientations depending on the application and space constraints. They can be mounted parallel to each other on parallel shafts, or they can be mounted at right angles using additional components such as bevel gears or shafts with appropriate bearings.

In summary, there is a wide range of sizes and configurations available for spur gears, including different pitch diameters, module sizes, number of teeth, pressure angles, profile shifts, hub configurations, materials, coatings, and mounting orientations. The selection of the appropriate size and configuration depends on factors such as torque requirements, speed, load capacity, space constraints, and specific application needs.

editor by CX 2023-09-05