Product Description

Product Description

SGR planetary gear motor

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industry |

|---|---|

| Hardness: | Hardened |

| Type: | Planetary Gear |

| Material: | Cast Iron |

| Manipulate Way: | Robotics |

| Changes Way: | Mixed |

| Customization: |

Available

| Customized Request |

|---|

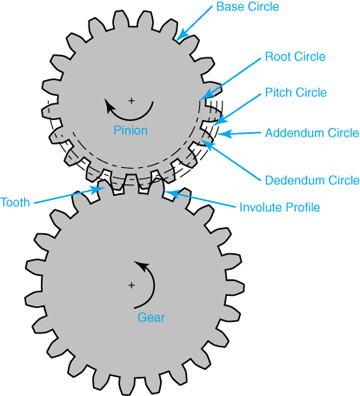

Can spur gears be used in precision manufacturing equipment?

Yes, spur gears can be used in precision manufacturing equipment. Here’s a detailed explanation:

Precision manufacturing equipment requires high accuracy, repeatability, and reliability to produce intricate and precise components. While other gear types like helical gears or bevel gears are commonly used in precision applications, spur gears can also be suitable in certain scenarios.

1. Low-Speed Applications:

Spur gears are well-suited for low-speed applications where high precision is required. In precision manufacturing equipment, such as milling machines, lathes, or grinding machines, where controlled and precise rotational motion is essential, spur gears can provide the necessary power transmission with accuracy.

2. Linear Actuators and Positioning Systems:

Spur gears can be used in linear actuators and positioning systems within precision manufacturing equipment. These systems require precise movement control, and spur gears can convert rotary motion into linear motion accurately. By incorporating precision-ground spur gears with proper backlash control, highly accurate positioning can be achieved.

3. Tooling Systems:

Spur gears are employed in tooling systems used in precision manufacturing equipment, such as indexing heads and rotary tables. These systems enable precise and repeatable positioning of workpieces or cutting tools. Spur gears with high precision tooth profiles and low backlash are utilized to ensure accurate tool positioning and consistent machining results.

4. Measuring and Inspection Equipment:

In precision manufacturing, gear systems are also utilized in measuring and inspection equipment. Spur gears can be incorporated into gear trains within instruments like coordinate measuring machines (CMMs) or optical comparators to translate linear or rotary motion into precise measurement data. The gear systems in these instruments require minimal backlash and high accuracy to ensure accurate measurements.

5. Customized Gear Systems:

In some cases, precision manufacturing equipment may require custom-designed gear systems to meet specific application requirements. Spur gears can be tailored and optimized for these custom gear systems, taking into account factors like gear tooth profile, material selection, and gear geometry. This allows for the creation of highly precise and specialized gear systems.

While spur gears have advantages in precision manufacturing equipment, it’s important to consider their limitations. Due to their design, spur gears may produce more noise and vibration compared to other gear types. Additionally, they are generally not suitable for high-speed or high-torque applications that demand continuous and smooth power transmission.

Overall, spur gears can be successfully used in precision manufacturing equipment for specific applications that require low-speed, precise motion control, accurate positioning, and measurement capabilities. Proper gear selection, high-quality manufacturing, and careful system integration are key to achieving the desired precision and performance in these gear applications.

How do you prevent backlash and gear play in a spur gear mechanism?

Preventing backlash and gear play is crucial for maintaining the accuracy, efficiency, and smooth operation of a spur gear mechanism. Here’s a detailed explanation of how to prevent backlash and gear play in a spur gear mechanism:

- Precision Gear Design: Ensure that the spur gears used in the mechanism are designed with precision and manufactured to tight tolerances. Accurate tooth profiles, proper tooth spacing, and correct gear meshing are essential to minimize backlash and gear play.

- Adequate Gear Tooth Contact: Optimize the gear meshing by ensuring sufficient tooth contact between the mating gears. This can be achieved by adjusting the center distance between the gears, selecting appropriate gear module or pitch, and ensuring proper gear alignment.

- Proper Gear Engagement Sequence: In multi-gear systems, ensure that the gears engage in a proper sequence to minimize backlash. This can be achieved by using idler gears or arranging the gears in a way that ensures sequential engagement, reducing the overall amount of play in the system.

- Backlash Compensation: Implement backlash compensation techniques such as preloading or using anti-backlash devices. Preloading involves applying a slight tension or compression force on the gears to minimize the free movement between the gear teeth. Anti-backlash devices, such as split gears or spring-loaded mechanisms, can also be used to reduce or eliminate backlash.

- Accurate Gear Alignment: Proper alignment of the gears is critical to minimize gear play. Ensure that the gears are aligned concentrically and parallel to their respective shafts. Misalignment can result in increased backlash and gear play.

- High-Quality Bearings: Use high-quality bearings that provide precise support and minimize axial and radial play. Proper bearing selection and installation can significantly reduce gear play and improve the overall performance of the gear mechanism.

- Appropriate Lubrication: Ensure that the gears are properly lubricated with the correct type and amount of lubricant. Adequate lubrication reduces friction and wear, helping to maintain gear meshing accuracy and minimize backlash.

- Maintain Proper Gear Clearances: Check and maintain the appropriate clearances between the gears and other components in the gear mechanism. Excessive clearances can lead to increased gear play and backlash. Regular inspections and adjustments are necessary to ensure optimal clearances.

- Regular Maintenance: Implement a regular maintenance schedule to inspect, clean, and lubricate the gear mechanism. This helps identify and rectify any issues that may contribute to backlash or gear play, ensuring the gear system operates at its best performance.

By following these practices, it is possible to minimize backlash and gear play in a spur gear mechanism, resulting in improved precision, efficiency, and reliability of the system.

It’s important to note that the specific techniques and approaches to prevent backlash and gear play may vary depending on the application, gear type, and design requirements. Consulting with gear manufacturers or specialists can provide further guidance on addressing backlash and gear play in specific gear mechanisms.

How do spur gears contribute to power transmission?

Spur gears play a crucial role in power transmission due to their specific design and tooth engagement. Here’s a detailed explanation of how spur gears contribute to power transmission:

- Direct Tooth Engagement: Spur gears have straight teeth that mesh directly with each other. This direct tooth engagement ensures efficient transfer of power from one gear to another. As the driving gear rotates, its teeth come into contact with the teeth of the driven gear, enabling the transfer of rotational motion and torque.

- Uniform Load Distribution: The teeth of spur gears distribute the transmitted load evenly across the gear surfaces. The straight, parallel teeth provide a larger contact area compared to other gear types, resulting in improved load-carrying capacity and reduced stress concentration. This uniform load distribution helps prevent premature wear and failure of the gears, ensuring reliable power transmission.

- Efficiency: Spur gears are known for their high efficiency in power transmission. The direct tooth engagement and parallel shaft arrangement minimize energy losses during rotation. The teeth mesh smoothly, resulting in minimal friction and reduced power dissipation. This efficiency is beneficial in applications where maximizing power transfer and minimizing energy waste are crucial.

- Speed and Torque Conversion: Spur gears allow for speed and torque conversion between the driving and driven shafts. By using gears with different numbers of teeth, the rotational speed and torque can be adjusted to match the requirements of the application. For example, a small gear driving a larger gear will result in a higher torque output at a lower speed, while a larger gear driving a smaller gear will result in a higher speed output at a lower torque.

- Directional Control: The arrangement of spur gears can be used to control the rotational direction of the driven shaft relative to the driving shaft. By meshing gears with opposite orientations (e.g., one gear with clockwise teeth and another gear with counterclockwise teeth), the direction of rotation can be reversed. This directional control is essential in applications where the desired motion needs to be reversed or changed.

- Multiple Gear Configurations: Spur gears can be combined in various configurations to form gear trains, allowing for complex power transmission systems. Gear trains consist of multiple gears meshing together, with each gear contributing to the overall power transmission. Gear trains can alter speed, torque, and direction, providing flexibility in adapting power transmission to specific requirements.

- Compatibility with Other Components: Spur gears are compatible with a wide range of other mechanical components, such as shafts, bearings, and housings. This compatibility allows for easy integration into different systems and machinery. Spur gears can be mounted on shafts using keyways, set screws, or other mounting methods, ensuring secure and reliable power transmission.

Overall, spur gears are essential in power transmission systems due to their direct tooth engagement, uniform load distribution, high efficiency, speed and torque conversion capabilities, directional control, compatibility with other components, and the ability to form complex gear trains. These characteristics make spur gears a versatile and widely used choice for transmitting power in various applications across industries.

editor by Dream 2024-05-03