Product Description

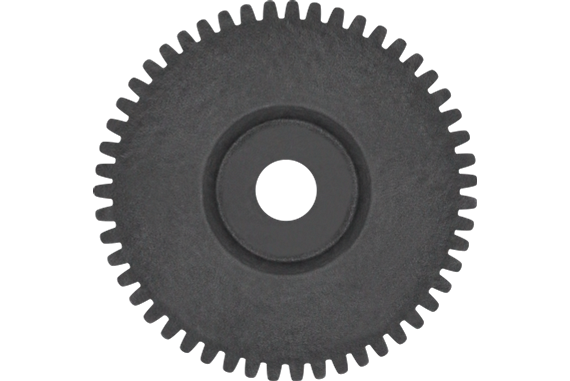

ODM OEM various transmission spur gear for motor

| Product Name | Sintered parts by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering – Powder Metallurgy |

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow |

Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Why Powdered Metals?

Significant cost savings.

Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials.

Production process of powder metallurgy

Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – Packing

Factory working shop view

Company Profile

CHINAMFG established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise E xamination I nstruments.

Strict Quality Control

With the “More diversity , More superior, More professional ” business purposes, we are committed to establish long-term friendship and CHINAMFG relationship with domestic and international customers to create a bright future .

Certification

Just contact with us with 2D or 3D drawing to start our cooperation! /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motorcycle, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Sintered Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spur gears be used in both horizontal and vertical orientations?

Yes, spur gears can be used in both horizontal and vertical orientations. Here’s a detailed explanation:

Spur gears are one of the most common types of gears used in various applications. They have straight teeth that are parallel to the gear axis and are designed to transmit power and torque between parallel shafts. The versatility of spur gears allows them to be used in different orientations, including horizontal and vertical configurations.

Horizontal Orientation:

In horizontal applications, where the gear shafts are positioned parallel to the ground, spur gears are widely utilized. Horizontal orientations are commonly found in machinery such as conveyor systems, automobiles, industrial equipment, and many other applications. Spur gears in horizontal configurations can efficiently transmit power and torque between shafts, providing reliable operation and smooth gear engagement.

Vertical Orientation:

Spur gears can also be used in vertical orientations, where the gear shafts are positioned perpendicular to the ground. Vertical gear arrangements are often encountered in applications such as wind turbines, elevators, vertical conveyor systems, and various industrial machinery. In these cases, the weight of the gears and any additional loads acting on them must be considered to ensure proper load distribution and support. Adequate lubrication and proper gear design, including tooth profile and material selection, are important factors to ensure reliable and efficient operation in vertical orientations.

When using spur gears in vertical orientations, some additional considerations may be necessary due to the effects of gravity and potential oil leakage. In vertical applications, gravity can affect the distribution of lubricant, potentially leading to inadequate lubrication of gear teeth. Proper lubrication techniques and lubricant selection should be employed to ensure sufficient film thickness and minimize wear. Additionally, seals or other measures may be required to prevent oil leakage, especially in applications where high-speed rotation or high loads are involved.

It’s important to note that while spur gears can be used in both horizontal and vertical orientations, the specific design and configuration of the gear system should be evaluated to ensure optimal performance and longevity. Factors such as load distribution, gear alignment, lubrication, and material selection should be carefully considered based on the intended orientation and operating conditions of the gear system.

Consulting with gear manufacturers, engineers, or industry experts can provide further guidance on the suitability and design considerations when using spur gears in horizontal or vertical orientations.

What is the purpose of using spur gears in machinery?

In machinery, spur gears serve several important purposes due to their unique characteristics and capabilities. Here’s a detailed explanation of the purpose of using spur gears in machinery:

- Power Transmission: Spur gears are primarily used for power transmission in machinery. They transfer rotational motion and torque from one shaft to another, allowing machinery to perform various tasks. By meshing the teeth of two or more spur gears together, power can be transmitted efficiently and reliably throughout the machinery.

- Speed Reduction or Increase: Spur gears enable speed reduction or increase in machinery. By combining gears with different numbers of teeth, the rotational speed can be adjusted to match the desired output speed. For example, using a larger gear driving a smaller gear can increase the speed output while reducing the torque, while the opposite arrangement can decrease the speed while increasing the torque.

- Torque Amplification: Spur gears can amplify torque in machinery. By using gears with different numbers of teeth, the torque can be adjusted to match the required output. For example, using a smaller gear driving a larger gear can increase the torque output while reducing the speed, while the opposite arrangement can decrease the torque while increasing the speed.

- Directional Control: Spur gears provide directional control in machinery. By meshing gears with opposite orientations, the rotational direction of the driven shaft can be reversed or changed. This directional control is crucial for machinery that requires bi-directional motion or needs to change the direction of operation.

- Mechanical Advantage: Spur gears offer a mechanical advantage in machinery. By utilizing gear ratios, spur gears can multiply or divide the force exerted on the input shaft. This mechanical advantage allows machinery to generate higher forces or achieve precise movements with reduced effort.

- Precision Positioning: Spur gears facilitate precise positioning in machinery. The accurate tooth engagement of spur gears ensures precise control over rotational motion, making them suitable for applications that require precise positioning or synchronization of components. Machinery such as CNC machines, robotics, and automation systems often rely on spur gears for accurate movement and positioning.

- Compact Design: Spur gears have a compact design, making them suitable for machinery with space constraints. They can be arranged in-line, parallel, or at right angles, allowing for efficient power transmission in tight spaces. Their compactness enables machinery to be designed with smaller footprints and optimized layouts.

- Reliability and Durability: Spur gears are known for their reliability and durability in machinery. The direct tooth engagement and uniform load distribution result in efficient power transmission with reduced wear and stress concentration. When properly lubricated and maintained, spur gears can withstand heavy loads and operate reliably over extended periods.

- Cost-Effectiveness: Spur gears are often cost-effective in machinery applications. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings. The availability of spur gears in various sizes and materials further enhances their cost-effectiveness.

By utilizing spur gears in machinery, engineers and designers can achieve efficient power transmission, speed and torque control, directional versatility, mechanical advantage, precise positioning, compact design, reliability, durability, and cost-effectiveness. These advantages make spur gears a popular choice in a wide range of machinery applications across industries.

What are the benefits of using a spur gear mechanism?

Using a spur gear mechanism offers several benefits in various applications. Here’s a detailed explanation of the advantages of using a spur gear mechanism:

- Simplicity: Spur gear mechanisms are relatively simple in design, consisting of cylindrical gears with straight teeth. Their simplicity makes them easy to manufacture, assemble, and maintain. They have fewer components compared to other types of gear mechanisms, resulting in lower complexity and potentially reduced costs.

- Efficiency: Spur gears exhibit high efficiency in power transmission. The teeth of spur gears mesh directly, resulting in minimal energy loss during transmission. The simplicity of their tooth profile allows for efficient power transfer, making them an energy-efficient choice for many applications.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in-line, parallel to each other, or at right angles using additional components such as bevel gears. This flexibility in arrangement allows for efficient power transmission in tight spaces.

- Versatility: Spur gears are versatile and can be used in a wide range of applications. They are available in various sizes, configurations, and materials, allowing them to be tailored to specific needs. Spur gears can handle different torque and speed requirements, making them suitable for both low and high-speed applications.

- High-Speed Capability: Spur gears can achieve high rotational speeds due to their straightforward design and direct tooth engagement. They are capable of transmitting power efficiently at high speeds, making them suitable for applications that require rapid motion or high rotational velocities.

- Precise Positioning: Spur gears provide accurate positioning due to their precise tooth engagement. The straight teeth allow for precise control of rotational motion, making them suitable for applications that require precise positioning, such as robotics, machinery, and automation systems.

- Cost-Effectiveness: Spur gears are often cost-effective compared to other gear mechanisms. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings.

- Reliability: Spur gears are known for their reliability and durability. The direct tooth engagement provides excellent load distribution, minimizing stress concentration and wear. When properly lubricated and maintained, spur gears can operate reliably for extended periods, making them suitable for demanding industrial applications.

- Wide Availability: Spur gears are widely available in the market, with various sizes, materials, and configurations to choose from. This availability ensures easy sourcing and replacement of gears when needed. Additionally, spur gears have been used for many years and have a well-established design and manufacturing process, leading to a robust supply chain.

These benefits make spur gear mechanisms a popular choice in numerous industries, including automotive, machinery, robotics, aerospace, appliances, and more. Their simplicity, efficiency, compactness, versatility, and reliability contribute to their widespread use in a wide range of applications.

editor by CX 2024-01-04