Product Description

| Product type | Sintered metal parts / Sector gears |

| Material | Stainless steel,Steel(Iron,)Brass,Copper (According to product design requirements) |

| Tolerance | ±0.01mm |

| Surface Treatment | As your requirement |

| Application | Tool industry,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, light industry products, sanitation machinery, etc. |

| Shape | Any other material and dimension depends on customers’ demand. |

| QC system | 100% inspection before shipment |

| Returned Goods Managing | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Payment terms | T/T at sight, Paypal, Western Union,etc. |

| Lead time | 7-15 working days as usual,It will based on the detailed order quantity. |

| Why Choose Us |

1. We have professional powder metallurgy production equipment and team;

2. We can accompany customers to develop products;

3. Just send an idea that you want to try, you don’t even need to know what powder metallurgy;

4. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

5. Our team will evaluate your inquiry and provide our offer within next 1~3 working days.

| Order Process |

1. You send us drawing or sample.

2. We carry through project assessment.

3. We give you our design for your confirmation.

4. We make the sample and send it to you after you confirmed our design.

5. You confirm the sample then place an order and pay us deposit.

6. We start producing.

7. When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers.

8. Trade is done, thank you!!

Additional Capabilities CAD Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering

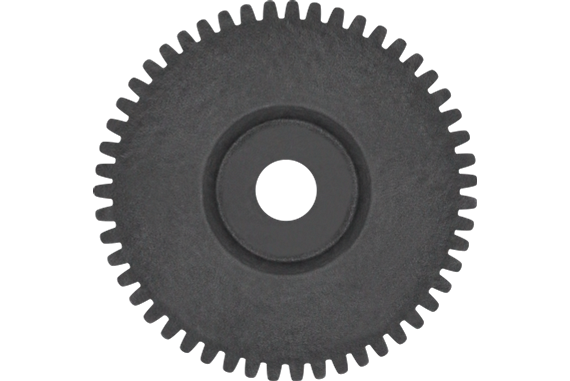

| Product Show |

| Some Parts We Manufacture |

Self-Lubricated Bushing

Structural Parts

Gears

| About Us |

DERYOUNG Technology company is a professional metal parts manufacturer, which with more than 20 years of experience in the development and production of sintered metals. Each year we produce more than 100 million premium sintered metal parts for our customers. We are mainly produce oil bearing, gear, and metal parts. We support our customers in the design and material selection of sintered parts, providing the best solution for your applied parts through our specialized equipment compression molds, furnaces, handling, sizing, deburring and impregnation processes.

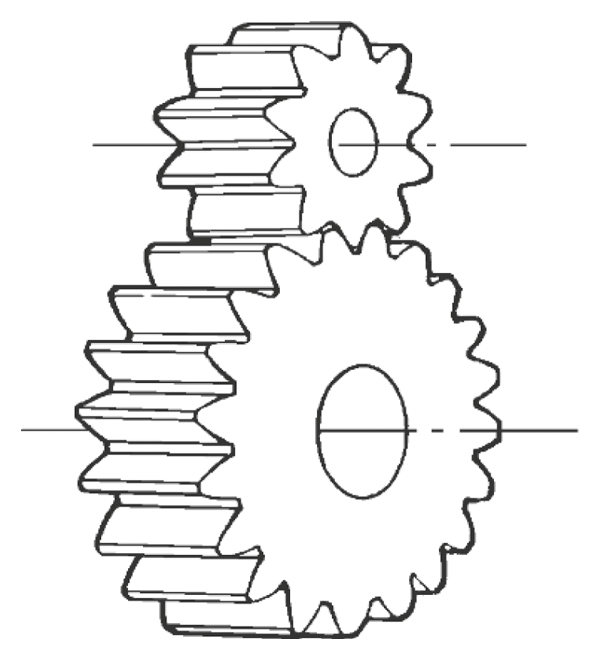

| Design Tips: Powder Metallurgy Gears |

1. Radius > 0.25 mm is required to manufacture the die;

2. Helical teeth should feature a helical angle < 30º in order to limit side pressure on the punches;

3. Introduction of a draft angle > 5º in the upper diameter reduce the tooling cost;

4. The distance between tooth root and central hub diameter must be: > 3 mm (Robust Tooling).

If you want to know more about the product, please send us a message.

| The Powder Metallurgy Manufacturing Process |

| FAQ |

| Q: How can I get the quotation? |

| A: Please send us information for quote: drawing, material, weight, quantity and request,w can accept PDF, ISGS, DWG, STEP file format. If you don’t have drawing, please send the sample to us,we can quote based on your sample too. |

| Q: What’s your MOQ? |

| A: In general 1000pcs,but can accept low quantity in some special conditions. |

| Q: Do you provide samples ? is it free or extra ? |

| A: Yes, we could offer the sample for free charge but do not pay the cost of freight. |

| Q: What about the leading time for mass production? |

| A: Honestly, it depends on the order quantity. Normally, 15 days to 20 days after your deposit if no tooling needed. |

| Q: What if the parts are not good? |

| A: We can guarantee good quality,but if happened,please contact us immediately, take some pictures, we will check on the problem,and solve it asap. |

| Q: What is your terms of payment ? |

| A: Payment=1000USD, 30% T/T in advance ,balance before shippment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you retrofit an existing mechanical system with spur gears?

Retrofitting an existing mechanical system with spur gears involves modifying or replacing certain components to incorporate spur gears into the system. Here’s a detailed explanation:

1. Evaluate the Existing System:

Begin by thoroughly evaluating the existing mechanical system to determine its design, function, and limitations. Identify the specific components that need to be retrofitted with spur gears and understand how the system operates.

2. Design Considerations:

Based on the evaluation, consider the design considerations for integrating spur gears into the system. This includes factors such as gear size, tooth profile, gear material, gear ratio, and torque requirements. Determine the specific gear specifications that are compatible with the existing system.

3. Gear Selection:

Select the appropriate spur gears that meet the required specifications. Consider factors such as gear quality, load capacity, noise level, efficiency, and compatibility with the existing system components. Choose gears from reputable manufacturers or consult with a gear specialist for guidance.

4. Gear Positioning and Alignment:

Determine the optimal positioning and alignment of the spur gears within the existing system. This involves identifying the gear locations, shaft connections, and ensuring proper alignment with other components such as bearings and couplings. Accurate positioning and alignment are crucial for efficient gear operation and longevity.

5. Modification or Replacement:

Based on the design considerations and gear selection, proceed with the necessary modifications or replacements. This may involve removing existing components, such as gears with different tooth profiles, and replacing them with the selected spur gears. Ensure proper installation and secure attachment of the new gears.

6. Lubrication and Maintenance:

Implement appropriate lubrication practices for the newly retrofitted spur gears. Consult gear manufacturers’ recommendations for lubricant type, quantity, and maintenance intervals. Proper lubrication ensures smooth gear operation, reduces wear, and extends gear life.

7. Testing and Validation:

After the retrofitting process, conduct thorough testing and validation of the modified system. Verify that the spur gears are functioning as intended, ensuring proper engagement, smooth operation, and adequate load handling. Address any issues or discrepancies discovered during testing.

8. Documentation and Training:

Create documentation detailing the retrofitting process, including gear specifications, installation procedures, and maintenance requirements. This documentation serves as a reference for future maintenance and helps ensure consistent gear performance. Additionally, provide training to relevant personnel on the operation, maintenance, and troubleshooting of the retrofitted system.

Retrofitting an existing mechanical system with spur gears requires careful planning, proper gear selection, precise installation, and thorough testing. By following these steps and considering the specific requirements of the system, it is possible to successfully incorporate spur gears and enhance the performance and functionality of the mechanical system.

What are the advantages and disadvantages of using spur gears?

Spur gears offer several advantages and disadvantages when used in mechanical systems. Here’s a detailed explanation of the advantages and disadvantages of using spur gears:

Advantages of Spur Gears:

- Simplicity: Spur gears have a simple and straightforward design, consisting of cylindrical gears with straight teeth. Their simplicity facilitates ease of manufacturing, installation, and maintenance.

- Efficiency: Spur gears are highly efficient in transmitting power from one shaft to another. They have minimal sliding friction between the gear teeth, resulting in high mechanical efficiency.

- Cost-Effectiveness: Due to their simple design and ease of production, spur gears are generally more cost-effective compared to other types of gears. They are widely available and can be manufactured in large quantities at a reasonable cost.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in parallel or stacked configurations to achieve the desired gear ratios within a confined space.

- High Load Capacity: Spur gears can handle high load capacities and transmit substantial amounts of torque. Their teeth are designed to distribute the load evenly across the gear face, resulting in improved load-bearing capabilities.

- Precision: Spur gears provide precise and predictable motion due to the simplicity of their tooth engagement. This makes them suitable for applications that require accurate positioning and synchronization.

Disadvantages of Spur Gears:

- Noisy Operation: Spur gears can produce noise during operation, especially at high speeds. The engagement of the gear teeth generates impact and vibration, resulting in noise that may require additional measures to mitigate.

- Axial Thrust: Spur gears generate axial thrust forces along the gear shafts due to the parallel arrangement of their teeth. This thrust must be properly managed using thrust bearings or other means to prevent excessive axial loading on the gear shafts.

- Limited Speed Ratio: Spur gears are primarily designed for applications with moderate speed ratios. They are less suitable for high-speed applications due to the limitations imposed by the tooth engagement and potential for increased noise and vibration.

- Unidirectional Operation: Spur gears are typically designed for unidirectional power transmission. Reversing the direction of rotation can cause noise, impact, and increased wear due to the abrupt change in tooth engagement.

- Prone to Wear: The sliding contact between the gear teeth in spur gears can result in wear over time, especially under heavy loads or inadequate lubrication. Regular maintenance and proper lubrication are necessary to minimize wear and extend gear life.

It’s important to consider these advantages and disadvantages when selecting gear types for specific applications. While spur gears are well-suited for many applications, other gear types, such as helical gears or bevel gears, may be more suitable in certain situations depending on the requirements and operating conditions.

Are there different sizes and configurations of spur gears available?

Yes, there are various sizes and configurations of spur gears available to suit different applications and requirements. Here’s a detailed explanation of the different options when it comes to sizes and configurations of spur gears:

Sizes: Spur gears come in a wide range of sizes to accommodate different torque and speed requirements. The size of a spur gear is typically specified by its pitch diameter, which is the diameter of the pitch circle. The pitch diameter determines the gear’s overall size and the spacing between the teeth. Spur gears can range from small gears used in precision instruments to large gears used in heavy machinery and industrial equipment.

Module: Module is a parameter used to specify the size and spacing of the teeth on a spur gear. It represents the ratio of the pitch diameter to the number of teeth. Different module sizes are available to accommodate various gear sizes and applications. Smaller module sizes are used for finer tooth profiles and higher precision, while larger module sizes are used for heavier loads and higher torque applications.

Number of Teeth: The number of teeth on a spur gear can vary depending on the specific application. Gears with a higher number of teeth provide smoother operation and distribute the load more evenly, whereas gears with fewer teeth are typically used for higher speeds and compact designs.

Pressure Angle: The pressure angle is an important parameter that determines the shape and engagement of the teeth. Common pressure angles for spur gears are 20 degrees and 14.5 degrees. The selection of the pressure angle depends on factors such as load capacity, efficiency, and specific design requirements.

Profile Shift: Profile shift is a design feature that allows modification of the tooth profile to optimize the gear’s performance. It involves shifting the tooth profile along the gear’s axis, which can affect factors such as backlash, contact ratio, and load distribution. Profile shift can be positive (when the tooth profile is shifted towards the center of the gear) or negative (when the tooth profile is shifted away from the center).

Hub Configuration: The hub refers to the central part of the gear where it is mounted onto a shaft. Spur gears can have different hub configurations depending on the specific application. Some gears have a simple cylindrical hub, while others may have keyways, set screws, or other features to ensure secure and precise mounting.

Material and Coatings: Spur gears are available in various materials to suit different operating conditions and requirements. Common materials include steel, cast iron, brass, and plastic. Additionally, gears can be coated or treated with surface treatments such as heat treatment or coatings to enhance their wear resistance, durability, and performance.

Mounting Orientation: Spur gears can be mounted in different orientations depending on the application and space constraints. They can be mounted parallel to each other on parallel shafts, or they can be mounted at right angles using additional components such as bevel gears or shafts with appropriate bearings.

In summary, there is a wide range of sizes and configurations available for spur gears, including different pitch diameters, module sizes, number of teeth, pressure angles, profile shifts, hub configurations, materials, coatings, and mounting orientations. The selection of the appropriate size and configuration depends on factors such as torque requirements, speed, load capacity, space constraints, and specific application needs.

editor by CX 2024-03-26